Magna

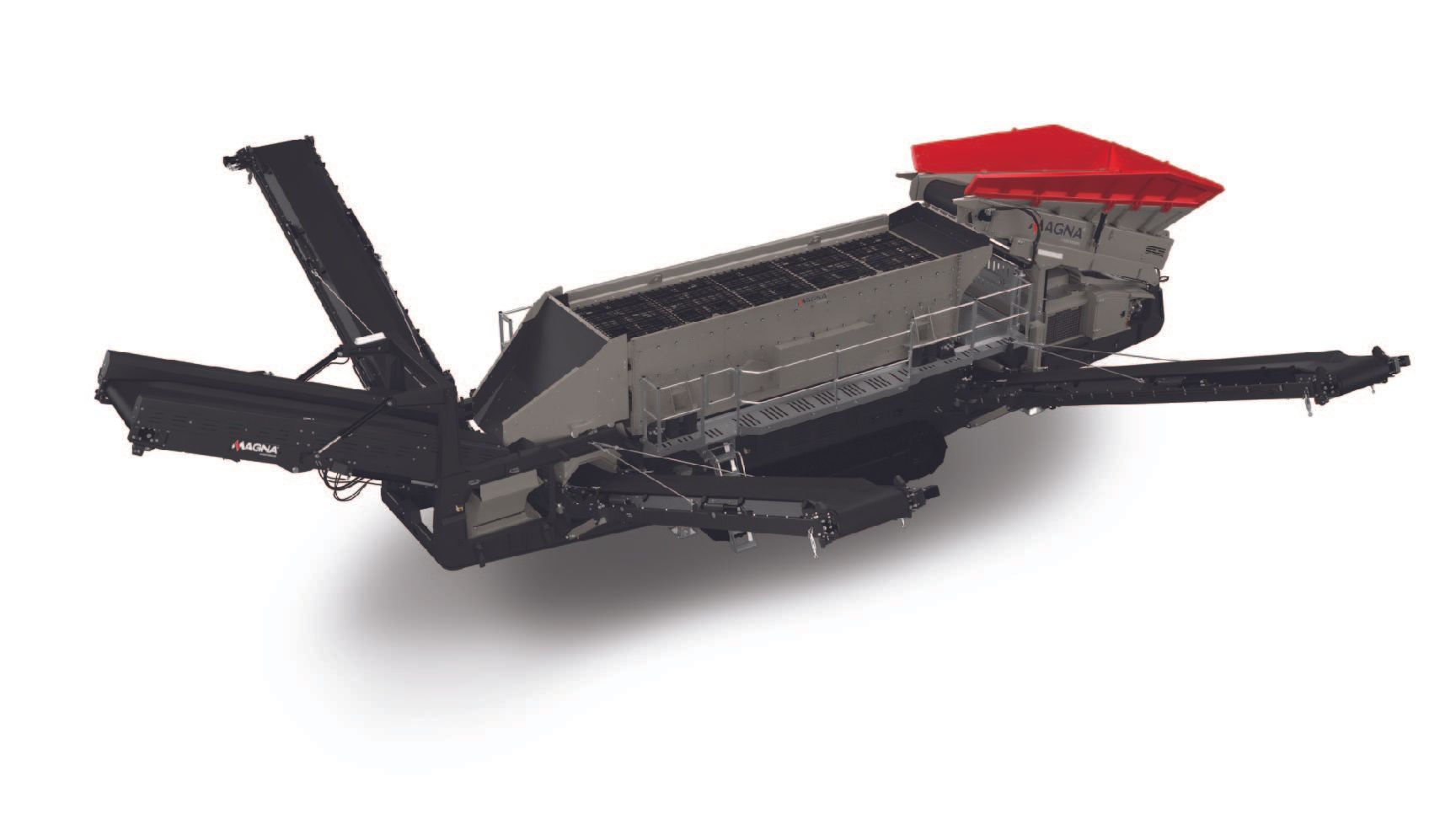

MT620H Horizontal Screen

The MAGNA MT620H is a horizontal screen designed for handling large quantities of sticky materials and delivering precise, fine sizing, making it perfect for numerous construction and mining contracts. It excels in handling materials such as natural and crushed aggregates, coal, iron ore, and recycled concrete and asphalt.

Slide title

Write your caption hereButton

TECHNICAL SPECIFICATIONS

FEATURES & BENEFITS

High capacity up to 800 tph / 881 US tph (depending on media sizes & material type)

Maximum feed size 250mm (10’’)

Maximum allowable feed size may vary depending on material type and screenbox media

Heavy duty wear resistant feed hopper

Quick set-up time

Maximum mobility with heavy duty, low ground pressure crawler tracks

Optional radio control system available if required

High performance hydraulics system

Galvanised maintenance platforms on both sides of screen

Hydraulically folding for transport

Heavy duty, triple shaft horizontal screenbox with adjustable stroke, angle & speed

Direct feed hopper with impact bars & rollers

Roll-in chute system

MAGNA telemetry as standard

SCREENBOX

6.1m x 1.93m (20’ x 6’ 4”) (All 3 decks)

3 deck triple shaft horizontal screenbox

Oval stroke adjustable up to maximum of 19mm

Oval stroke angle adjustable from 30º - 60º

Breaker-box with wear resistant steel replaceable wearplate

Hi-torque screen motor mounted direct to Screenbox, pulley driven

Marshmallow springs

Wear plates on pipeunits

Side tensioned all decks

Quick release wedge tensioning system (optional

depending on screen media)

Roll-in chute system

HOPPER

Target area: 5.23m (17’ 2’’) long x 2.7m (8’ 10”) wide

Hopper capacity: 8.2m3 (10.72 cu. yd.)

Feed in height: 3.4m (11’ 2”) (rear door lowered)

Feed in width (Rear): 2.8m (9’ 2”)

Hydraulic folding hopper sides

Wear resistant steel on hopper sides

BELT FEEDER

Drum centres: 4.36m (14’ 4”)

Drum diameter (drive): 375mm (14.8”)

Drum diameter (tail): 320mm (12.6”)

1300mm (52”) 4 ply plain belt

Direct drive system with twin gearboxes

Variable speed control

Impact bars and ‘extra heavy’ duty rollers fitted beneath belt

CONVEYORS

Underscreen

1500mm (60”) 3 ply plain belt

Direct drive system

Variable speed control

Drum centres: 6.25m (20’ 6”)

Drum diameter (drive): 270mm (10.6”)

Drum diameter (tail): 270mm (10.6”)

Finesize - Side Conveyor

900mm (36”) 3 ply plain belt

Angle adjustment: 14º - 25º

Stockpile height: 4.3m (14’ 1’’)

Stockpile capacity: 119m3 (156 cu. yd.)

Drum centres: 9.5m (31’ 2”)

Drum diameter (drive): 286mm (11.3”)

Drum diameter (tail): 203mm (8”)

• Hydraulically folding

• Impact bars under feedboot

• Direct drive system

• Variable speed control

Mid - Finesize & Mid-Oversize - Side Conveyor

Angle adjustment: 14o - 25o

Stockpile height: 4.4m (14’ 5’’)

Stockpile capacity: 129m3 (166 cu. yd.)

Drum centres: 8.92m (29’ 3”)

Drum diameter (drive): 286mm (11.3”)

Drum diameter (tail): 203mm (8”)

Hydraulically folding

Impact bars under feedboot

Direct drive system

Variable speed control

900mm (36”) 3 ply plain belt

Oversize - Tail Conveyor

Angle adjustment: 10o - 25o

Stockpile height: 4m (13’ 1’’)

Stockpile capacity: 95m3 (124 cu. yd.)

Drum centres: 5.15m (16’ 11”)

Drum diameter (drive): 286mm (11.3”)

Drum diameter (tail): 203mm (8”)

1400mm (56”) 4 ply plain belt

Direct drive system

Variable speed control

Impact bars

Conveyor slide out system to aid screen mesh changing

ENGINE

CAT C7.1 151 kW (202hp) @ 2200rpm