Magna

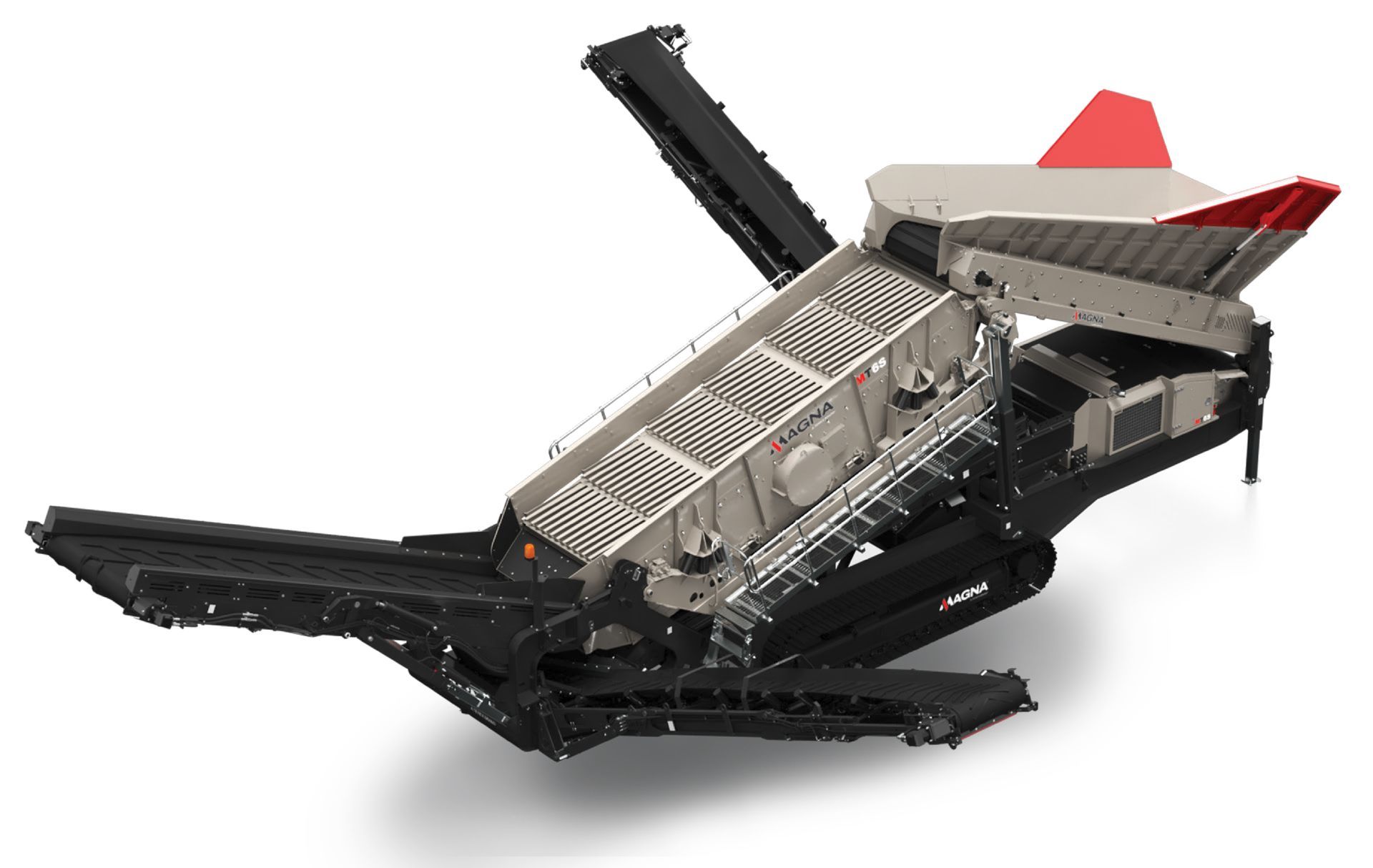

MT6S Scalping Screen

The MAGNA MT6S is a highly adaptable and robust screen designed for use in large-scale operations, including quarrying, mining, construction, demolition debris handling, topsoil processing and recycling. It can also handle applications including sand, gravel, coal, ore, and aggregates. The MT6S can process up to 800TPH and features a powerful 6,100mm x 1,830mm (20’ x 6’) screenbox for efficient screening.

Slide title

Write your caption hereButton

TECHNICAL SPECIFICATIONS

FEATURES & BENEFITS

High capacity up to 800 tph / 881 US tph (depending on media sizes & material type)

Versatile aggressive screen box can be easily adapted to suit many applications

Modular configuration screen box with 6.1m x 1.8m (20’ x 6’) top deck and 5.5m x 1.8m (18’ x 6’) bottom deck screen

Screen box angle can be hydraulically adjusted to an angle between 14 – 18°

Screen box discharge end can be hydraulically raised 600mm (24”) to facilitate efficient and easy media access and changing

All stockpiling conveyors are hydraulic angle adjustable with hydraulic extending head sections for maximum discharge & stockpile height

Apron feeder angle adjustable, lower position to accommodate crusher feed, high position provides reduced feeder incline angle when operated in direct feed mode from excavator/loader

SCREENBOX

Top deck: 6.1m x 1.83m (20’ x 6’)

Upper deck media: 40mm – 200mm

Bottom deck: 5.5m x 1.83m (18’ x 6’)

Bottom deck media: 100mm max

Tensioning top deck: Side

Tensioning bottom deck: End

Drive: Hydraulic with heavy duty bearing single shaft, 2 bearing

Catwalks: Galvanised access catwalk on both sides of screen

Screen Angle: 14° - 18°

Screen Speed: 900 rpm - 1000 rpm

Screen stroke Min/Max range: 8mm - 10mm

Screen stroke standard: 8mm Wear resistant liners on top deck discharge chute

Screen box discharge end raises hydraulically 600mm to facilitate mesh changing

Media options: Mesh, Punch Plate, Bofor bars, fingers and heavy duty sectional punch plate

Total screening area: 21.2m² (228 ft²)

HOPPER / FEEDER

Hopper Capacity: 10m³ (13.08 yd³)

Feed height: 3.27m - 4.16m (10’ 9” - 13’ 8”)

Feed in width: 1.7m - 2.48m (5’ 6” - 8’ 1”)

Drive: Hydraulic variable speed drive via high torque gearbox and heavy duty chain drive

Apron feeder dimensions: Width 1.1m x Length 5.18m (43” x 16’ 12”)

Speed: Variable, up to 24mpm

Abrasion Resistant steel pan apron feeder mounted with wide mouth opening

Hopper extensions Feed height: 4.9m - 5.29m (16’1” - 17’ 3”)

(Optional): Feed in width: 3.724m (12’ 2”)

CONVEYORS

Oversize Conveyor

Belt width: 1.6m (63”)

Belt spec: Chevron

Working Angle: Hydraulic raise/lower variable working angle - 14° to 24°

Speed: 52 mpm

Discharge Height: 4.55m (14’ 11”)

Stockpile capacity: 140.1m³ (183.2yd³) @ 24°

Hydraulically folding head section

Impact bars full length of conveyor

Steel skirted full length of conveyor

Transfer Conveyor

Belt width: 1.4m (55”)

Belt spec: Plain

Belt Speed: 99.4 mpm Conveyor fully skirted

Fines Conveyor

Belt width: 1.05m (41”)

Belt spec: plain

Working Angle: 25° Rosta scraper on head drum

Speed: variable speed, up to 122 mpm

Standard Discharge Height: 4.5m (14’ 09”)

Stockpile capacity: 136m³ (178yd³) @ 40°

Midgrade Conveyor

Belt width: 900mm (36”)

Belt spec: Chevron

Working Angle: 25°

Speed: variable speed, up to114 mpm

Standard Discharge Height: 4.35m (14’ 03”)

Stockpile capacity: 122m³ (159.6yd³) @ 40°

ENGINE

Tier 3: Caterpillar C7.1 151kW (202hp)