Magna

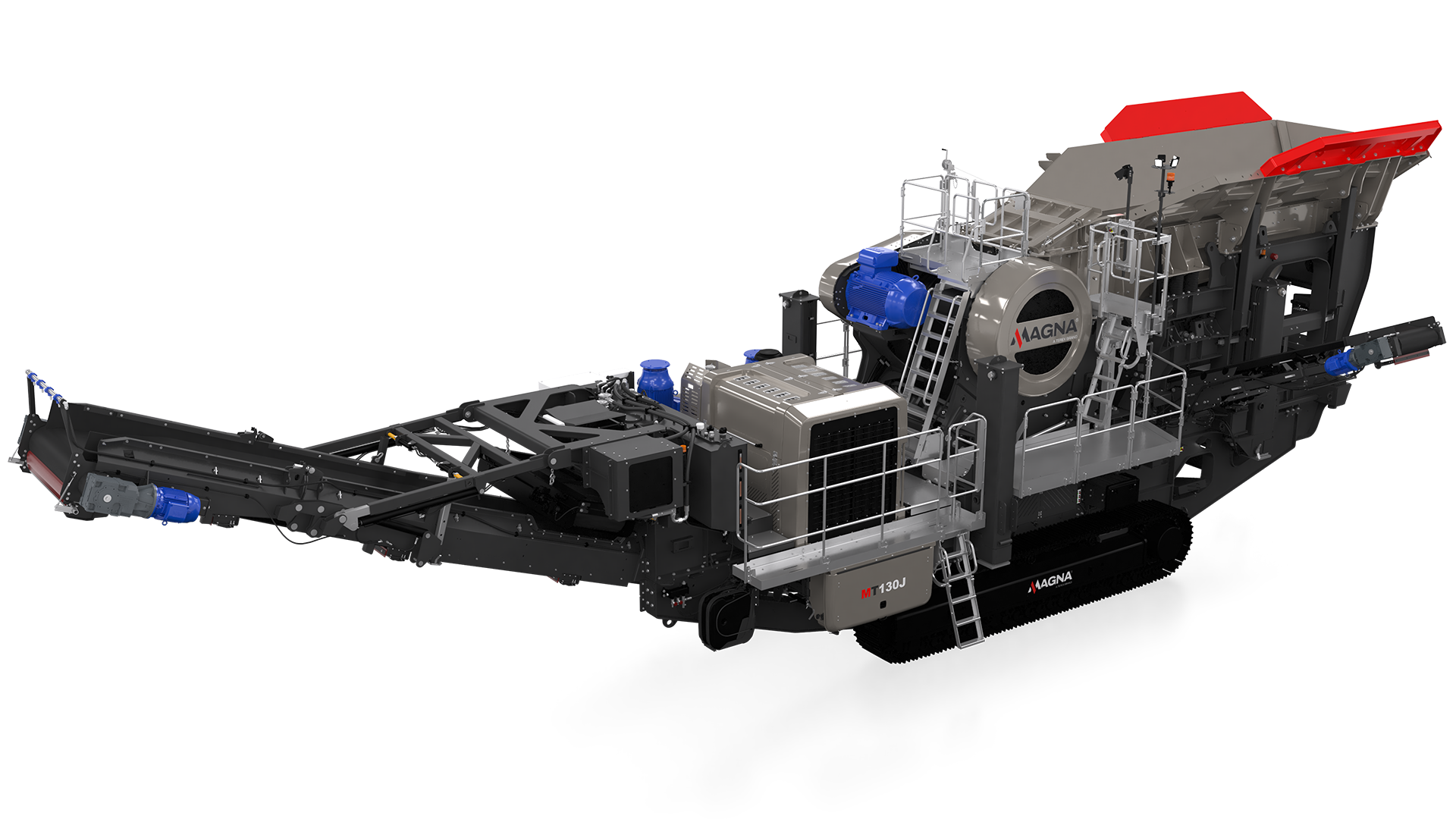

MT130J Jaw Crusher

The MAGNA MT130J mobile jaw crusher is the largest tracked jaw crusher in the MAGNA range and has been developed for large-scale quarry and mining operations. The machine can operate as standalone primary crusher or integrated into a mobile or static crushing and screening plant.

For easy transport movement between locations the plant can be split down and reassembled without the need for heavy crane assistance on site.

Slide title

Write your caption hereButton

TECHNICAL SPECIFICATIONS

FEATURES & BENEFITS

Output potential up to 1000tph / 1120 US tph - depending on material type & crusher settings.

The plant’s electrically driven power systems provide significant cost advantages and environmental efficiencies.

The large feed width and gape enables the crusher to accept larger and coarser material reducing the need for hammering of oversized product.

Automatic variable speed VGF ensures continuous choke feeding of the crushing chamber for optimal productivity.

High powered electric drive ensures precise chamber controls and reverse functionality for clearing blockages.

Fully hydraulic crusher fitting adjustment

Modern & user friendly PLC control system with auto start facility

Dust suppression system

MAGNA telemetry as standard

Radio remote control as standard

JAW CRUSHER

Crusher type: Single toggle Jaw with hydraulic setting adjustment

Feed opening: 1300mm x 1000mm (51” x 39”)

Bearings: Self aligning spherical rollers

Lubrication: Grease

Drive: Electric variable speed drive with reversable operation (200kw 6 Pole drive motor)

Minimum setting: 125mm (5”) CSS

All setting measured from root to tip & subject to suitability of feed material

This plant has been designed for both heavy duty and mining applications where appropriate.

For maximum material strength of 500kN 10% Fines, 300MPa compressive strength.

Maximum setting: 250mm (10”) CSS standard jaws

Hydraulic adjustment: Hydraulically adjusted CSS using wedge system. Electric push button control

HOPPER

Hopper type: Hydraulic locking from ground level

Hopper length: 6.1m (20’)

Hopper width: 2.8m (9’2”) standard 3.7m (12’ 2”) with extensions

Hopper feed heights: 6.35m (20’ 10”) - with extensions fitted

Hopper capacity: 13.5m3 (17.64 cu.yds3)

Hopper body: Abrasion resistant feed hopper with hydraulic struts and pins

• Reinforced hopper side walls

• 15mm (5/8’’) AR450 wear resistant steel plate

*Optional large flare hopper extensions:

Capacity: 15.3m3 (20.01 cu.yd.)

VIBRATING GRIZZLY FEEDER

Type: Spring mounted vibrating pan & grizzly feeder, Electric driven independent screen below VGF

Vibrating Unit: Twin electric vibrator motors

Length: 5.5m (18”)

Width: 1.35m (4’ 5”) standard

Drive: Electric

Grizzly: 2 replaceable stepped cartridge type grizzlies 75mm (3’’) nominal aperture, self cleaning

Underscreen: 50mm (1.6”) rubber screen cloth fitted as standard

Feeder speed range: 450-900 RPM

VGF Feed area: 2.7m x 1.38m (8’10” x 4’6”)

VGF Screening Area: 2.9m x 1.38m (9’6” x 4’6”)

PRODUCT CONVEYOR

Conveyor type: Troughed plain belt conveyor

Design:

Hydraulic raise & lower facility from 2.6m(8’ 6”) to 4.2m(13’ 7”)

Can be raised or lowered while crushing.

Fully removable modular unit to aid access & maintenance.

Lower section raises & lowers for optimum ground clearance.

Belt type: EP630 with 8mm top & 2mm bottom cover, vulcanised

Belt width: 1400mm (4’ 6”)

Discharge height: 4.2m (13’7”) to the underside of drum

Stockpile volume: 136m3 (178yds3) @ 40o

Drive: 15kw twin electric motor & planetary gearbox drive

Tunnel: Fully tunnelled lower section

Feedboot: Mild steel plate with abrasion resistant steel liners at feed point

Belt adjustment: Screw adjusters at head drum

Belt scraper: SCS style

Lubrication: Low level remote head drum grease points

Skirting:

Wear resistant rubber skirts fitted up to magnet

Impact bars and wear resistant liners at feed point

ENGINE

CAT C15 403kW (540hp)